Organizational Procedure

It’s two o’clock in the morning when your phone rings. It’s the on-call hospital administrator at your facility. A natural disaster has struck, and your hospital must remain fully operational for the next 72-96 hours with limited external resources. The 96-hour emergency management plan at your hospital is being activated, and a media press conference is set to take place at 5:00 a.m. The next question you hear is, “Do we have enough medications on hand to provide care to our patients for the next 3-4 days?” As the pharmacy director, which medications will you prioritize as the most medically necessary?

While this scenario might seem like something out of a blockbuster movie, you may have already faced it or addressed a similar question during your triennial accreditation survey preparation. At the core of this situation is the crucial question: Is the medication list in your emergency playbook robust enough to meet the challenge, or will it leave you scrambling?

If you haven’t created an essential medications list before, or are looking to revisit your current one, it’s important to start by defining your scope. According to the World Health Organization (WHO), essential medications are those that satisfy the priority health care needs of a population. Your scope consists of two main components: the setting you are covering and the types of medications you are including.

First, determine what your setting needs to plan for. Then, define which medications are essential for your patients. This should reflect the disease prevalence and public health relevance within your patient population, including common conditions, infrequent but possible scenarios, and rare but potential disease states. Both the identification of disease states and the selection of necessary medications should be approached in a multidisciplinary fashion, leveraging the expertise of specialists in each area to pinpoint the truly essential medications.

When creating a disease state-specific medication list, it’s helpful to identify primary and secondary alternatives when possible. For organizations that serve as centralized hubs within a larger health system, it might be most feasible to set a minimum reorder point at 7-8 days for each medication based on system-wide use. This strategy ensures the larger hub can maintain control over product availability during challenging times. However, given the diversity of your patients and the “rare or potential disease states,” this approach can lead to substantial costs and high levels of waste on seldom used but essential products.

For smaller or leaner facilities, establishing reduced reorder points for secondary agents or even a non-stocking status for infrequent secondary agents, when the primary medication is readily available, can help reduce carrying costs. This approach does require closer attention to stock levels to ensure availability and a commitment to daily ordering.

Regardless of the facility size, partnering with vendors to identify replacement product programs and collaborating with other hospitals in the area to understand each location’s stock can help cut costs and reduce waste.

Lastly, establishing a follow-up procedure to ensure the medications on your emergency list remain in stock is essential. If your automation or inventory management system allows you to set standard stock products in both decentralized and centralized inventory, you can align your inventory reports with cycle counts to ensure products are always replaced after expiration and never inadvertently removed.

For hospitals in regions where emergencies are more common, whether year-round or seasonally, consider creating more frequent automated dashboards to alert your buyer of stock issues. Additionally, revisiting your day’s supply based on current patient usage or embedding the emergency medication evaluation within the formulary approval process can help maintain the stability of your list as treatments and needs evolve.

Steps to Consider When Creating an Essential Medication List for Your 96-Hour Emergency Management Plan:

- Form a multidisciplinary team.

- Include representatives from pharmacy, clinical departments, administration, inventory management, and key disaster management members.

- Ensure involvement of specialists for different disease states to get a comprehensive perspective.

- Define essential medications.

- Prioritize medications based on disease prevalence, public health relevance, and patient needs within your specific setting. Identify primary medications and establish secondary alternatives for each condition.

- Validate the list with input from specialists and clinical teams to ensure completeness and accuracy.

- Develop inventory management protocols.

- Set minimum reorder points based on medication use patterns. For centralized hubs, establish a minimum reorder point at 7-8 days for each medication. For smaller or leaner facilities, consider reduced reorder points or non-stocking status for infrequent secondary agents.

- Use automation and inventory management systems to track stock levels and align reports with cycle counts.

- Create automated dashboards to alert buyers of stock issues, especially in regions prone to emergencies.

- Collaborate with vendors and other local hospitals.

- Collaborate with nearby hospitals to create a network of transparency and cost reduction by sharing information on high-cost, low-utilization medications.

- Work with vendors to identify product replacement programs or consignment opportunities to reduce costs and ensure supply.

- Explore options for emergency restocking and rapid replenishment.

- Create a plan for ongoing monitoring and continuous improvement.

- Schedule regular reviews of the essential medication list to update it based on changing patient needs and treatment protocols. Revisit day’s supply based on current patient usage and embed the emergency medication evaluation within the formulary approval process.

- Maintain communication with clinical teams, administration, and other stakeholders to ensure the list remains relevant and effective.

In a previous article, I covered 5 key things that hospital pharmacy leaders need to know about medication safety [SEE: '5 Things You Need to Know NOW About Medication Safety']. Now, we need to put this into action. In this article, I’ll touch on 4 things to jump start medication safety at your organization!

- Review and share reported medication errors. I have a colleague whose career in medication safety started when she was asked to categorize medication errors as part of a modified work assignment (she was a hospital pharmacist back then) while she was transitioning back from maternity leave. She was only asked to categorize the errors but as she read through them, she started asking the question, ‘What are we doing about these errors?’ That was the impetus for the creation of a dedicated medication safety role at her organization. I cannot emphasize enough the power of these reported errors when they are reviewed AND SHARED! Bring awareness to what is happening to both those on the front line as well as leaders above you who can influence and prioritize resources to projects that will reduce the risk of medication errors.

- Utilize the Institute for Safety Medication Practices (ISMP) Newsletters. As a hospital pharmacist many moons ago, I was fortunate enough to be part of an organization that shared the ISMP newsletters with staff. It was eye-opening (and scary!) to read about medication errors that occurred at other organizations. It can also be overwhelming to realize how much risk exists! That said, don’t try to boil the ocean. Instead, identify one or two items each quarter (or even each year) that you want to address for your pharmacy or hospital and just focus on that. While some recommendations may require a heavy lift (e.g., a system enhancement to the organization’s electronic health record), others could be easier to implement and lead to small but quick wins.

- Assign small medication safety related projects to interested staff. As a pharmacy leader, remember that you do not have to do everything. Instead, as medication safety related projects arrise, leverage the talent, expertise, and interest from your staff. This is a win-win-win all the way around. The hospital or pharmacy benefits from the project, the employee is engaged and feels valued for being able to contribute in a unique way, and the manager gets something they has been meaning to address off their plate. Standardizing a process (example: a process for unit dosing medications), creating a quick reference card/table (example: creating a laminated table of where certain medications can be infused based on unit), or redesigning an automated dispensing cabinet matrix drawer or tower to optimize efficiency of refills AND minimize look alike errors, are all very ‘doable’ by staff, with guidance.

- Hire a dedicated medication safety officer! I strongly believe that every medical center needs a dedicated medication safety officer to set the medication safety vision, identify opportunities to improve the medication-use process, and lead efforts and initiatives to prevent medication errors. This simply cannot be another hat that a manager or director wears in addition to a multitude of other responsibilities on their plate. In a later article, I’ll provide insight into what to look for in a medication safety officer.

Children's National Hospital Division of Pharmacy boosted its pharmacy operational efficiency by merging datasets across its workflow platforms into a central data repository, from which many co-variables were then accounted for. With aggregated workload data from 180+ employees across 10,000 shifts, they implemented user-friendly dashboards, ensuring accuracy through collaboration.

The result? Major operational and clinical improvements, highlighting the power of data integration and automation in healthcare. This signals a bright future for efficiency with advancements in automation, predictive AI, and data analytics, poised to revolutionize pharmacy operations and patient care. Upon implementation, one of the Operations Manager voiced being “empowered to track, trend, and share employee metrics during their monthly 1on1s with their direct reports especially now being able to account for differences in workload in different shifts, days, and whether training or not”.

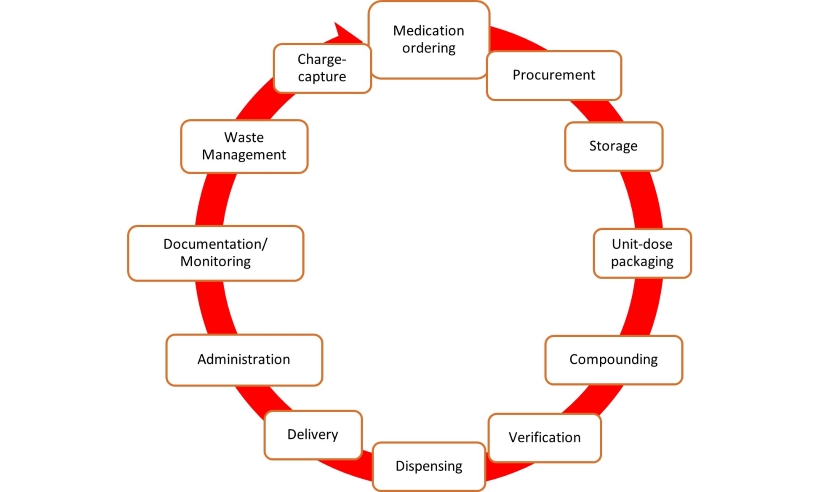

Fig 1: Lifecycle of medication in the hospital. Each stage of the medication lifecycle has different disconnected technology platforms with different datasets needed to be merged into a data warehouse.

Healthcare organizations face a data explosion, with the sector generating a significant share of global data. Despite this, healthcare lags in data utilization due to privacy concerns and disjointed systems. Children’s National Hospital, like many others, operates various disconnected platforms, hindering data analysis and workflow understanding. Manual data handling strains resources, urging the need for automated solutions. To enhance efficiency and patient care, hospitals are turning to digital health strategies, integrating analytics platforms. Children’s National Hospital aimed to streamline pharmacy data management through automation, addressing staffing challenges and burnout. This report outlines the implementation process and key insights gained.

Setting the Stage: Navigating Pharmacy Innovation

Children’s National Hospital, recognized as a top-ranking facility in neonatal intensive care and overall pediatric care by U.S. News & World Report, prioritizes pediatric well-being. With a dedicated team of over 180 professionals, patient safety remains paramount. To improve medication management, the hospital sought modernization. Recognizing the inefficiency of Excel, which consumed 25 hours monthly and incurred extra costs, the pharmacy initiated a digital analytics pilot. Technical hurdles and data inaccuracies necessitated a transition to streamline medication lifecycle management.

The Blueprint for Pharmacy Efficiency

To meet diverse data reporting needs like daily huddle, Department of Health DOH on-demand, and C-suite reporting, an integrated platform was sought. Preceding tool development, similar organizations were studied for best practices. Some of those studied included a rural Maryland hospital analytics-driven approach with reduced spending on acetaminophen by 78%, a multihospital system in Central NC using clinical analytics to monitor high-risk medications, and a large multihospital and clinical system in South Florida streamlining its formulary after acquiring more hospitals and clinics to its network.

Critical platforms were integrated in phase I, with less critical ones and financial data slated for phase II. Real-time reporting measures encompassed dose preparation and verification efficiency, shift efficiency, dispenses to outside clinics, and controlled substance dispenses. Validation involved collaborative efforts between the Division of Pharmacy Services team and the analytics platform provider's Director of Healthcare Consulting and Implementation.

Powering Pharmacy Performance

Post-implementation, the platform analyzed eight real-time datasets, covering over 180 employees and 10,000 shifts, providing comprehensive insights into operational and clinical efficiency. Access to real-time dashboards centralized data from the entire medication lifecycle, allowing for streamlined measurement of performance indicators. Integration of previously siloed platforms enhanced leadership's visibility into employee efficiency, resulting in a 75.5% reduction in open shift hours. The dashboards facilitated accurate staff probation decisions and reduced manual data entry, freeing up 25 hours monthly in bandwidth. Phase II integration included census and capacity data, enabling predictive staffing level assessments with <5% variance to actual.

Navigating Challenges Learned in Pharmacy Automation

The Division of Pharmacy at Children's National learned key lessons in automating and integrating data tracking and would like to share for others considering adopting new data and analytics platforms. They include:

- Buy-in: Securing support from leadership and frontline staff is crucial, emphasizing increased efficiency and improved outcomes.

- Time: Phase 1 took over 300 hours across 6-8 months, requiring adequate bandwidth and avoiding peak busy seasons.

- Technological: Managing IT governance, including HIPAA compliance, and addressing cybersecurity concerns with the IT department are essential. Renegotiating contracts with existing vendors may be necessary.

- Project staff-mix: Some staff lacked a blend of clinical and technical expertise, hindering effective integration and tailoring of the analytics software. Avoid using a non-clinical project manager and rather utilize a pharmacist with both clinical and technical knowledge to facilitate quicker implementation.

The Future of Data Automation in Healthcare

Automating data analysis fits the future of healthcare, aligning with digital health trends. Recent advancements include vaccine management and sterile automated compounding. Predictive analytics and AI are increasingly vital in diagnosis, treatment, and regulation. Predictive AI can enhance pharmacy efficiency by forecasting drug demand and managing medications. Integration with Cerner EHR aims to bolster analytical trends, identify cost-saving opportunities, and improve safety reporting.

Conclusion

Implementing a unified data platform improved pharmacy efficiency and real-time reporting at Children’s National Hospital. Integrating clinical and operational data is crucial for hospital effectiveness. As healthcare automation advances, digital analytics platforms are vital for capturing and enhancing clinical performance.

We urge other healthcare systems to merge data and share results to maximize efficiency and outcomes.

The issue of drug shortages is an enduring problem, dating back to the early 1920s with the first traceable shortage being insulin. National tracking of drug shortages began in 2001, highlighting the persistent nature of this challenge. Despite over a century worth of awareness and opportunity, patients and healthcare providers continue to grapple with drug shortages. Although the idea of “drug shortages” is not exclusive to certain regions or facility type, each healthcare entity navigates these overlapping challenges in its own unique way, reflecting the widespread but varied impact of this ongoing issue.

We started the first quarter of 2024 by breaking historical records, reaching an all-time high of 323 active drug shortages, with nearly half being generic sterile injectable (GSI) medications. The challenges in patient care due to interruptions in GSI availability, coupled with financial implications, are significant. It's estimated that hospitals collectively spend upwards of $600 million per year managing drug shortages. This includes direct costs associated with more expensive, non-preferred products, increased labor costs due to alternative preparation requirements, higher operational carrying costs from increased standard stock amounts, and perhaps most frustratingly, waste once the shortage is resolved.

While no product interruption is ideal, some are more understandable than others. These include manufacturing delays due to equipment maintenance or repair, precautionary batch failures due to suspected quality control issues, or natural disasters. On the flip side, shortages caused by single-source producers dominating the market, significant violations leading to an FDA Form 483, or a diluted product margin resulting in negative value-added situations across multiple manufacturers are less palatable within a fragile system responsible for the health of a nation.

More recently, in response to these concerns, the U.S. Department of Health and Human Services (HHS) released a jointly sponsored white paper titled "Policy Considerations to Prevent Drug Shortages and Mitigate Supply Chain Vulnerabilities in the United States." In this white paper, HHS emphasized the importance of developing and implementing a collaborative, shared accountability model for drug shortage prevention. This model consists of two key components: the Manufacturer Resiliency Assessment Program (MRAP) and the Hospital Resilient Supply Program (HRSP).

The combined program aims to enhance market transparency for GSIs, promote volume-based purchase decisions with a sustainability focus rather than a "race-to-the-bottom" approach, and improve reliability by incentivizing investments in supply chain resilience and diversification. This includes initiatives such as expanding domestic manufacturing and production of key ingredients. However, there's also the potential for hospitals to face penalties under this framework.

Although an official statute has not yet been enacted into law, this is a critical issue. Institutions should take this opportunity to thoughtfully develop and refine clear processes and policies for managing drug shortages at the local level. The following factors should be considered when constructing your inventory management plans during a shortage and preparing to understand your financial position throughout.

Important discussion points to consider when developing your drug shortage management process:

- Work closely with your external pharmacy procurement stakeholders. Vendors such as drug manufacturers, wholesalers, and Group Purchasing Organizations (GPOs) can be invaluable partners. Each partner has the potential to add significant value to your organization.

- Internally, build relationships with key stakeholders across all care areas that may be impacted by a drug shortage. This ensures you understand who can be involved in developing a detailed mitigation plan.

- Determine the appropriate level of inventory for your facility and establish protocols for adjusting standard stock amounts during a shortage. This is a crucial component of financial stewardship during a shortage. Avoid panic-buying all available products in every dose and size to prevent product wastage and tighter constraints caused by a bullwhip effect.

- Conduct frequent huddles with purchasing team members to maintain a consistent understanding of product availability in the market. Daily structured huddles, even if brief, are ideal. Provide broader communication on a weekly basis to all pharmacy leadership for situational awareness, with meaningful escalation as needed. For larger Integrated Delivery Networks (IDNs), establish a system-level committee to review new, active, and pending mitigation plans.

- Organize a response process for activating a drug shortage plan and proactively plan mitigation strategies when monitoring indicates a potential shortage. Start discussions early with key pharmacy staff and select providers to determine preferred treatment alternatives. Do not assume that a pending shortage will be automatically communicated to the relevant stakeholders.

- Leverage your informatics and automation technologies to alert and guide providers to the shortage mitigation strategy, ensuring that any available product is reserved for patients who need it most.

- Identify ways to stretch your current supply to benefit as many patients as possible. Strategies include reducing automated dispensing cabinet PARs, strategically planning compounding for products that contain more than one dose, and shifting inventory from low-use to high-use areas. Work with key internal stakeholders to ensure changes are made with full awareness, for instance in the previous examples, ensure billing units do not result in overcharging during batch preparation of doses or that a PAR reduction does not interfere with urgent response protocols.

- Finally, revisit partnerships and how they can support you during drug shortages. Partners such as wholesalers, GPOs, and manufacturers can collaborate on plans to purchase short-dated products that would otherwise be wasted or enroll in commitment programs that ensure sustainable product availability through predictable and consistent volume needs. Both approaches can reduce your financial burden during shortages, with commitment programs offering proactive shortage prevention; understanding that these programs are most impactful prior to a shortage occurring.

Soaring drug prices are putting the squeeze on pharmacies, but you have the power to resist the trend. Advanced analytics can help your pharmacy loosen hyperinflation’s grip.

From 2022 to 2023, drug prices surged by 15.2%, on average, on top of an 11.2% increase the previous year, significantly outpacing inflation. This past year’s increase constitutes an average difference of $590 per drug, putting big pressure on providers nationwide.

The increases are especially bad news for rural hospitals, where over 600 facilities, or 3 in 10, were at risk of closure in 2023 due to financial instability.

Mitigating the impact of rising costs is an industry priority: 71% of hospital pharmacy participants recently stated that streamlining pharmacy purchasing and procurement was an essential priority for them this year.

The good news is they can do just that.

Where’s the opportunity?

There’s plenty of opportunity among the 40,000 to 60,000 NDC prices hospitals must evaluate daily, given nearly 2,500 preferred NDCs and eight NDC options per therapeutic group.

Most hospitals have been managing this supply chain with low-tech tools like Excel. Many also rely on traditional siloed GPO tools, wholesale portals, and TPA software. Despite pharmacies’ best efforts, this fragmentation hampers data-driven decision-making, creating gaps, deficiencies, and waste.

Traditional procurement approaches also prioritize compliance over financial performance, missing potential improvements in fiscal optimization and sustainability. Even hospitals using newer analytics focus mostly on inventory tracking and supplier consolidation.

Cost-reduction reality

Pharmacy supply chain teams need more. In my view, they need integrated analytics created specifically to optimize spending through blended prices, real-time cost pricing data, and clear visibility into potential savings.

Hospital executives generally understand this need and intend to address it. More than half say data-driven improvements in supply chain management can improve margins by at least 1% to 3%, according to a Sage Growth Partners Survey. The challenge, however, has been creating the right solution.

Fortunately, some hospital systems are adopting purpose-built innovations that surface potential cost savings and elevate the highest-potential opportunities to the top of an integrated dashboard.

These solutions provide transparency around all available drug options to ensure a hospital system gets the best prices and is fully stocked with the drugs it needs. From 2023 to 2024, there was a significant increase in the adoption of new software technologies to help combat purchasing problems, with 25% of respondents turning away from their wholesaler tools compared to 8% the previous year.

Millions of dollars recouped

We looked at 140 hospitals using state-of-the-art purchasing-optimization technology and workflows developed by pharmacists. These leaders saved $27 million in 2023 through real-time data-driven recommendations for better purchasing options. The recommendations considered preferred NDCs, GPO compliance, availability, and WAC, GPO, and 340B ratios.

For the pharmacy professional, a useful real-time purchasing-optimization dashboard provides three simple workflows:

- A direct savings workflow that flags overcharges and recommends lower-priced options for identical products and hard-dollar ROI.

- A cost avoidance workflow that flags 340B insights, contract management opportunities, and impending price increases, preventing overcharges before they happen.

- An oversight workflow that monitors spending, shortages, and GPO compliance.

Relief is in reach

Now, any hospital system can have a bird’s-eye perspective of these workflows in their organization, viewing similar sites in “groups” and facilitating standardized buying practices where applicable. Buyers can dive deeper into any recommended change with a simple click.

Developing such a system doesn’t have to be a major IT undertaking. It’s more about gathering primary data: a wholesaler account list, a 12-month inventory history, 340B covered entity status, and GPO’s preferred NDC list. Standard templates help pharmacy departments connect to major wholesalers.

As a hospital pharmacy, there’s not a lot you can do to prevent drug prices from rising. But you can do more to find the best available price for every purchase. Analytics, dashboards, and the data you already have point the way.

In an evolving time for Pharmacies across the nation, picture a blank canvas. You may ask why? What does this have to do with pharmacy and healthcare? I want you to take a journey with me to the small beginnings I did not despise when it came to our Pharmacy department.

Insight Hospital Chicago is the oldest hospital in Chicago. Its located on the south side of Chicago in a community where the age expectancies vary between 10 minutes of each other. The hospital is a safety net and prizes on the 340B drug program. The spring of 2022 presented the real test. Insight was 100% independent from the previous company. The pharmacy department was a blank canvas with great potential for success.

One of the first discussions was to become dually accredited as a specialty pharmacy. My physical perception of that goal was questionable. We were only an outpatient retail pharmacy servicing a lower number of the hospital and community every week. My inward perception was based on faith that all things are possible. This was the passion that drove us to achieve this vision. When it came to specialty accreditation, we decided to pursue Utilization Review Accreditation Commission (URAC) first. The blank canvas was beginning to have color now. URAC accreditation was very extensive and intense. We rebuilt and reshaped the outpatient pharmacy in many ways. The policies, procedures and workflow were targets that help to provide infrastructure to the department. Within less than one year the outpatient received approval for full accreditation with no findings. This was a mark in history for the pharmacy department and for the hospital. Who would have thought the pharmacy would be able to achieve this in such a quick time. The doors were opening now in many ways. We were now able to get access to limited distributions drugs (LDD), had the payors open more to the pharmacy which helped to support the business. The hospital also gained more awareness in the community. The canvas was becoming fuller and more colorful.

The next accreditation we received for 9 months was Accreditation Commission for Health Care (ACHC). After this second accreditation, the outpatient pharmacy was put on the map. To become dual accredited within one year served as a success and legacy. Our Insight Chicago Pharmacy has gained more traction and notoriety. The canvas went from being blank and empty to full, vibrant and history in the making. Our pharmacy department considered the small beginnings and used that as a guide for the legacy we have now.

Telehealth is a program that has taking off with the Pharmacy at Insight. Through the Collaborative Drug Therapy Management (CDTM) program, the team is able to partner with providers and give the best patient experience. With this program in place, our prescription volume has exponentially increased from where we started. We can now firmly say the pharmacy department at Insight Chicago is flourishing. This also provides great support for the hospital, which is a big pillar in the community. The canvas is now filled and beautiful. It is diverse and versatile. It wouldn’t have gotten this way without a team. Everyone in the pharmacy department worked as a team. From the pharmacy technician to the Chief Pharmacy Officer (COP), there was communication and teamwork. This is what made the vision manifest and come to life!

To conclude, all things are possible when it comes to new beginnings. Health systems across the nation have pharmacy departments that have been long standing and already build our full workflow and operations. The question becomes, what happens when you meet a pharmacy department that is not? Where do you start on making it fully functional, unique and with purpose? Consider the blank canvas journey that I went through and know there are open skies of opportunities. One can start with an vision and believing from within.

The inclusion of virtual pharmacy in the inpatient hospital setting is a significant shift towards integrating technology with healthcare, presenting unparalleled opportunities to elevate patient care. As we progress towards the 2030 American Society of Health-System Pharmacists (ASHP) healthcare initiatives, the adoption and optimization of Virtual Pharmacy stand out as key priorities for integrated health systems.

Strategic Implementation and Focus Areas

The strategic deployment of Virtual Pharmacy has revolutionized traditional pharmacy roles by transitioning aspects of order verification to environments with fewer distractions. Virtual Pharmacy associates are equipped with a focused work queue that aligns with the organization's strategic goals. This approach has allowed Virtual Pharmacists to concentrate on high-volume orders needing quick turnaround times, specifically targeting departments such as the Emergency Room, Surgery, Maternity, Postpartum, and Nursery. By reallocating these tasks off site, on-site pharmacists are afforded the bandwidth to focus more on operational duties and specialized clinical care, perfecting the balance between efficiency and quality patient care.

Operational Efficiency and Patient Care

An extensive review of hospital operations in one health system from January 2018 to June 2023 illuminates the substantial impact of Virtual Pharmacy, particularly within the Emergency Department (ED).

Efficiency in Order Verification

A notable achievement within the Virtual Pharmacy initiative has been the significant improvement in the order verification process. Order verification within 10 minutes significantly improved by 16.7%, jumping from 73.6% to 90.3%. This progress not only met but exceeded the system's target, confirming over 90% of orders are verified within a critical time limit. This is only made possible by the improved efficiency of Virtual Pharmacy.

Accelerated Antibiotic Administration

The efficacy of Virtual Pharmacy extends to enhancing the timeliness of antibiotic administration for critical cases:

- Pre-Virtual Pharmacy: 28.2%

- Post-Virtual Pharmacy: 50.9%

- One specific Location:

- Baseline: 35.3%

- During Virtual Pharmacy: 68.6% (↑33.3%)

- After Virtual Pharmacy Removal: 54.9% (↓13.7%)

These statistics highlight Virtual Pharmacy's vital role in speeding up essential interventions, thereby improving patient outcomes.

Expansion Opportunities and Patient Engagement

Virtual Pharmacy's existing structure offers significant potential for growth and expansion to the outpatient settings. Examples include Medication Therapy Management (MTM) and patient counseling. By providing personalized care through tailored MTM and counseling, Virtual Pharmacy could significantly boost patient engagement, promote shared decision-making and adherence to treatment plans. This approach not only elevates patient safety and outcomes but also presents scalable opportunities for the further integration of Virtual Pharmacy services within the healthcare delivery framework.

Conclusion

Virtual Pharmacy is not an entirely new concept but is at the forefront of healthcare innovation and is strategically positioned to fulfill the ambitious goals of the 2030 ASHP healthcare initiatives. Through strategic implementation, operational efficiencies, and expansion opportunities, Virtual Pharmacy is reshaping the healthcare landscape, setting new benchmarks for efficiency, clinical outcomes and patient engagement. As the healthcare sector continues to evolve, the ongoing enhancement and integration of Virtual Pharmacy will be crucial in realizing a more efficient and patient-centric healthcare ecosystem.

Drug shortages are becoming a pervasive global issue. In the United States alone, there were 309 active drug shortages at the end of the second quarter of 2023 — the most in nearly a decade and close to the all-time high of 320 shortages, according to a report by the American Society of Health-System Pharmacists. Causes of these shortages are varied and complex, ranging from manufacturing and quality issues to unexpected demand surges, posing significant risks to public health. However, the responsible use of evolving technology, especially Artificial Intelligence (AI), can be a valuable asset in addressing the drug shortage crisis. The National Artificial Intelligence Act of 2020 defines AI as “a machine-based system that can, for a given set of human-defined objectives, make predictions, recommendations or decisions influencing real or virtual environments. Here are a few ways in which healthcare systems can utilize AI-driven approaches to mitigate the impact of drug shortages.

AI-Driven Forecasting and Inventory Management: One of the most significant ways AI can combat drug shortages lies in its ability to forecast shortages before they occur. Conventional methods of demand forecasting rely on manual analysis and decision making and often fall short in capturing dynamic factors influencing supply and demand. In contrast, AI algorithms swiftly analyze diverse data sources such as historical shortage data, production capacity, regulatory trends, and market dynamics, achieving high accuracy in predicting potential shortages. By capitalizing on these predictions, healthcare systems can take proactive measures to mitigate shortages, such as increasing production capacity or securing alternative suppliers. Furthermore, AI-powered epidemiological models can forecast changes in disease prevalence and treatment demand, enabling healthcare systems to anticipate shifts in medication requirements and adjust procurement strategies accordingly.

Supply Chain Optimization: Pharmaceutical supply chains are complex and are notoriously susceptible to disruptions. However, AI’s data analysis prowess holds promise in optimizing the pharmaceutical supply network. Through predictive analytics and machine learning algorithms, AI can identify vulnerabilities in the supply chain, anticipate disruptions, and recommend strategic interventions to minimize risks, preventing shortages from happening in the first place.

Production Optimization/Quality Control: Manufacturing quality issues and production inefficiencies are major reasons for drug shortages. AI can enhance production processes within pharmaceutical manufacturing facilities, minimizing drug shortages. By analyzing production data in real-time, AI can identify inefficiencies, optimize manufacturing workflows, and reduce waste. Furthermore, AI-driven quality control systems can enhance the reliability and safety of pharmaceutical products by detecting defects, anomalies, or deviations from specifications in real-time, minimizing the likelihood of production delays due to regulatory compliance issues.

Alternative Therapies/Enhanced Clinical Decision Support: AI can support clinical decision-making in managing drug shortages. Though still in its early stages, AI-driven clinical decision support systems (CDSS) can analyze patient data, treatment guidelines, and drug availability information to recommend alternative therapies or dosing regimens when preferred medications are unavailable. By integrating clinical expertise with real-time data analytics, AI-driven CDSS can empower healthcare providers to navigate complex treatment scenarios and optimize patient outcomes amidst drug shortages.

Overall, AI presents a promising path forward in addressing the persistent issue of drug shortages. By integrating AI-based tools, healthcare systems can not only predict and prevent shortages but also optimize supply chains, streamline production, and support informed clinical decision-making. While challenges remain, responsible implementation can ensure that AI’s potential in tackling drug shortages is fully realized, achieving better patient outcomes and improving the global public health.

The responsibility to uphold the sterile compounding standards set forth by The Joint Commission (TJC) and the updated USP Chapter <797> is paramount. The revised guidelines, which came into effect in late 2023, necessitate a proactive approach to ensure compliance and safeguard patient health.

With an eye on the latest pharmacy research and expert guidelines, below are some steps and recommendations to help ensure your hospital pharmacy is up to date on the requirements:

1.) Policy and procedure review

Begin with a thorough review and revision of your current sterile compounding policies and procedures. Ensure they are in strict alignment with the updated USP <797> guidelines. This includes clear definitions and protocols for CSP categorization, beyond-use dating, and personnel qualifications. Emphasize a culture of continuous improvement, encouraging feedback from your team members to help refine these processes.

2.) Empower your team through education and competency

Invest in providing ongoing, comprehensive training programs for your staff. The programs should cover critical aspects, such as aseptic techniques, garbing procedures, and environmental monitoring, and aligning them with the latest standards. Consider utilizing innovative training tools like simulation-based education to enhance and improve learning outcomes. Regular competency assessments are crucial to ensure that all pharmacy personnel are not just trained, but proficient.

3.) Environmental monitoring and control enhancements

Adopt a zero-tolerance policy toward lapses in environmental quality within compounding areas. Implement state-of-the-art environmental monitoring technologies to track air quality, surface cleanliness, and temperature/humidity levels in real-time. These systems can provide actionable data to prevent contamination risks.

4.) Establish a robust quality assurance framework

Quality assurance (QA) is the backbone of sterile compounding compliance. Develop a comprehensive QA program that encompasses all aspects of the compounding process, from material sourcing to final CSP verification. Regular audits, both internal and external, should be part of your QA strategy to identify and rectify compliance gaps promptly.

5.) Advanced garbing and hand hygiene protocols

Reinforce the critical importance of proper garbing and hand hygiene among your team members. Consider implementing interactive training sessions and routine competency checks to ensure adherence. Consider the adoption of newer, more effective garbing materials and hand hygiene products to further reduce contamination risks.

6.) Documentation

In the world of sterile compounding, we know that documentation is king. Maintain comprehensive, easily accessible records of all training sessions, competency assessments, environmental monitoring results, and QA audits. These records not only demonstrate compliance during TJC surveys, but also provide invaluable data for ongoing process improvements.

7.) Engaging leadership and fostering a safety culture

Active engagement from hospital leadership is essential to drive compliance initiatives and to assess the current plan. Present compelling cases for the resources needed to meet TJC requirements, emphasizing the link between compliance, patient safety, and organizational reputation. Foster a culture of safety and excellence, where every team member feels empowered to contribute to compliance efforts.

8.) Continuous improvement through feedback and innovation

Adopt an open-door policy for feedback on sterile compounding practices from your team. Encourage innovation by staying abreast of advancements in compounding technology and practices. Participate in professional forums and networks to share insights and learn from peers across the industry.

9.) Prepare for TJC surveys with mock inspections

Consider conducting regular mock TJC surveys to prepare your team and identify any potential compliance issues. These simulations should cover all aspects of the survey process, including document review, staff interviews, and direct observation of compounding activities. Use the findings to make immediate corrections and long-term improvements.

By considering and following these recommendations, you can ensure your hospital pharmacy meets the requirements set forth by TJC and USP<797>. This proactive approach to compliance will safeguard patient health, enhance the efficacy of compounded medications, and solidify your pharmacy’s reputations for healthcare excellence.

Achieving and maintaining compliance is a continuous journey that requires dedication, adaptability, and a relentless commitment to excellence. By empowering your team, investing in advanced technologies, and fostering a culture of continuous improvement, you can navigate the complexities of sterile compounding regulations and improve patient care.

Pharmacy leaders at hospitals and health systems juggle a variety of issues and activities every day. From my decades of experience, I’m familiar with the operational, clinical, financial, and regulatory responsibilities we manage. It’s challenging but rewarding.

While we can’t solve all challenges overnight, we can make progress in one area: regulatory compliance. Let’s start by focusing on accreditation. We’ll look at specific (and perhaps lesser known) standards issues I have seen surveyed, with practical strategies to prepare.

Policies and documents required for compliance

These are items I call “easy A’s,” or foundational policies you should just have in place. While they may seem like you’re just “checking a box,” if you don’t have these, your hospital may be at risk for citation. I recommend three areas to focus on:

- POLICIES: Do you have policies, SOPs, or written processes that address medication shortages, recalls, patient self-administration of drugs, investigational drug continuity, automatic stop orders, and ADRs? These are common policies that get overlooked.

- DOCUMENTS: Do you have criteria for drug selection (formulary), performance improvement plans and data?

- REGULAR REVIEW AND APPROVAL: Do you have processes in place to consistently review your formulary, LASA list, high-alert list, override lists, emergency medication supplies, policies, order sets, and standing orders?

ACTIONS TO CONSIDER:

- Policies don’t necessarily have to be full policies, but they should be written documents and must match your practice.

- Formulary demographic sheets or logs should have standardized information for each drug that is proposed for addition, and all should be filled in or marked NA to show they were considered. Work with your hospital Quality department to ensure there are medication-related PI projects being tracked and reported.

- Not all reviews are required every year but start by establishing a cadence to keep them current.

Medication security considerations

CMS says medications are secure if they cannot be accessed by unauthorized individuals. Controlled substances must be locked. These considerations are probably compliant in most of your hospital areas, but some might slip by.

- CRASH CARTS: Most of us use the breakaway numbered seals on our carts, but these ensure integrity of the drugs inside, not security. For this reason, controlled substances cannot be stored in them unless the cart is locked with a padlock, which could present a patient safety risk when trying to access emergency drugs.

- NON-CONTROLLED DRUGS: Are your crash carts under constant observation? Are they parked where they cannot be seen (like alcoves or halls)? If so, you may be at risk for non-compliance, as the seals aren’t locks and they can be opened undetected, which is a security concern.

- UNLICENSED PERSONNEL: Materials Management, EVS, and others may need to handle and/or be around non-controlled medications pursuant to performing their job duties. This is compliant, provided you have a policy that states so.

ACTIONS TO CONSIDER

- Ensure that no padlocks are used on crash carts. Any controls that might be needed during a code should be kept in separate, locked storage that can be quickly accessed.

- Placing crash carts in a locked room or in a place with close supervision will solve the challenge of unmonitored access.

- If any non-licensed individuals enter medication rooms or handle drugs as a regular activity (such as transporting cases of IV fluids), identify them in an approved policy.

Whether you’re getting ready for an accreditation survey next week or months down the road, you can never be too prepared. Compliance with the standards of accrediting bodies reduces the risk of patient harm, and isn’t that the ultimate goal?